Protection Method Deep Dive: Ex “nR”, The Restricted-Breathing Enclosure

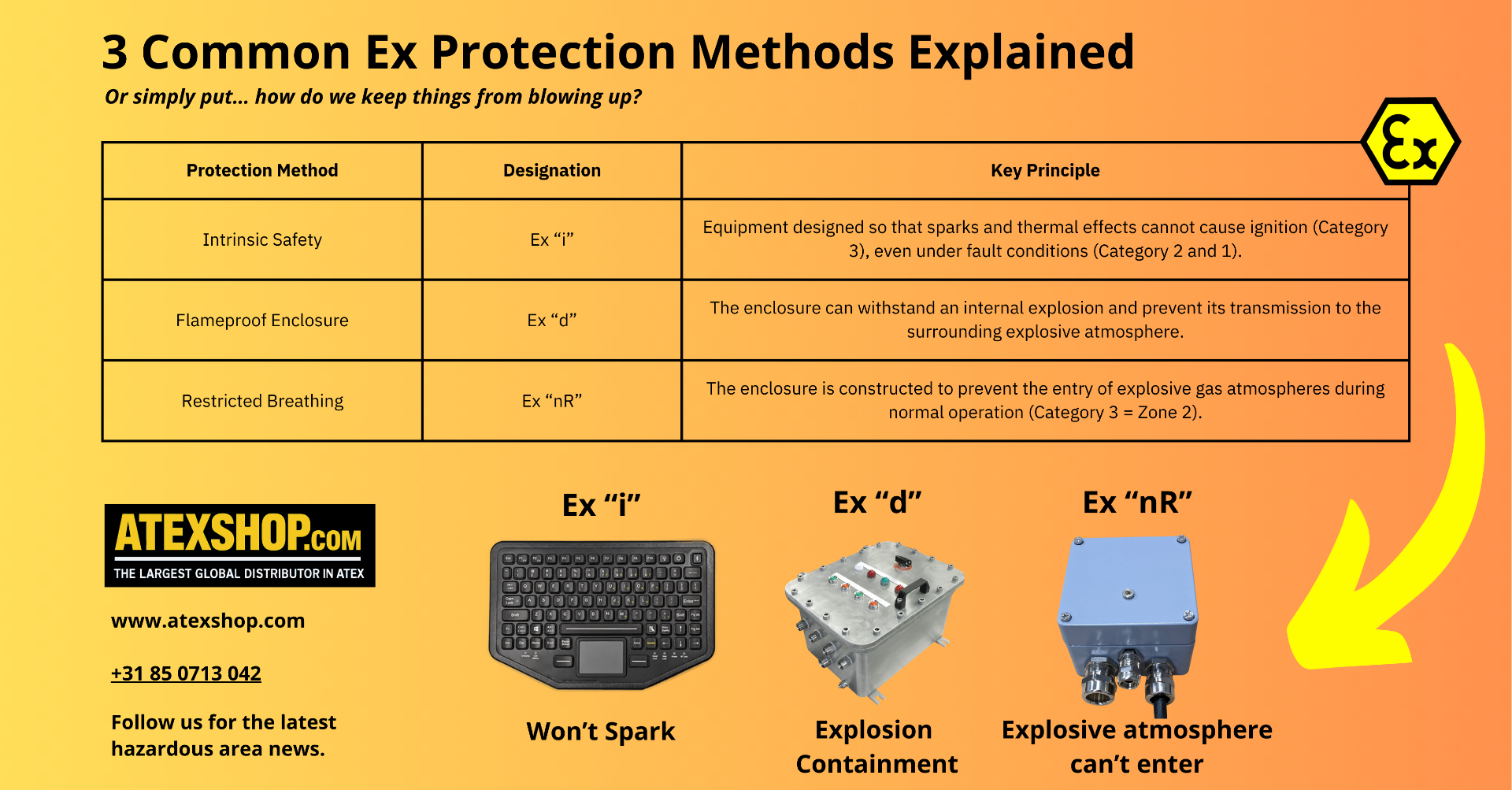

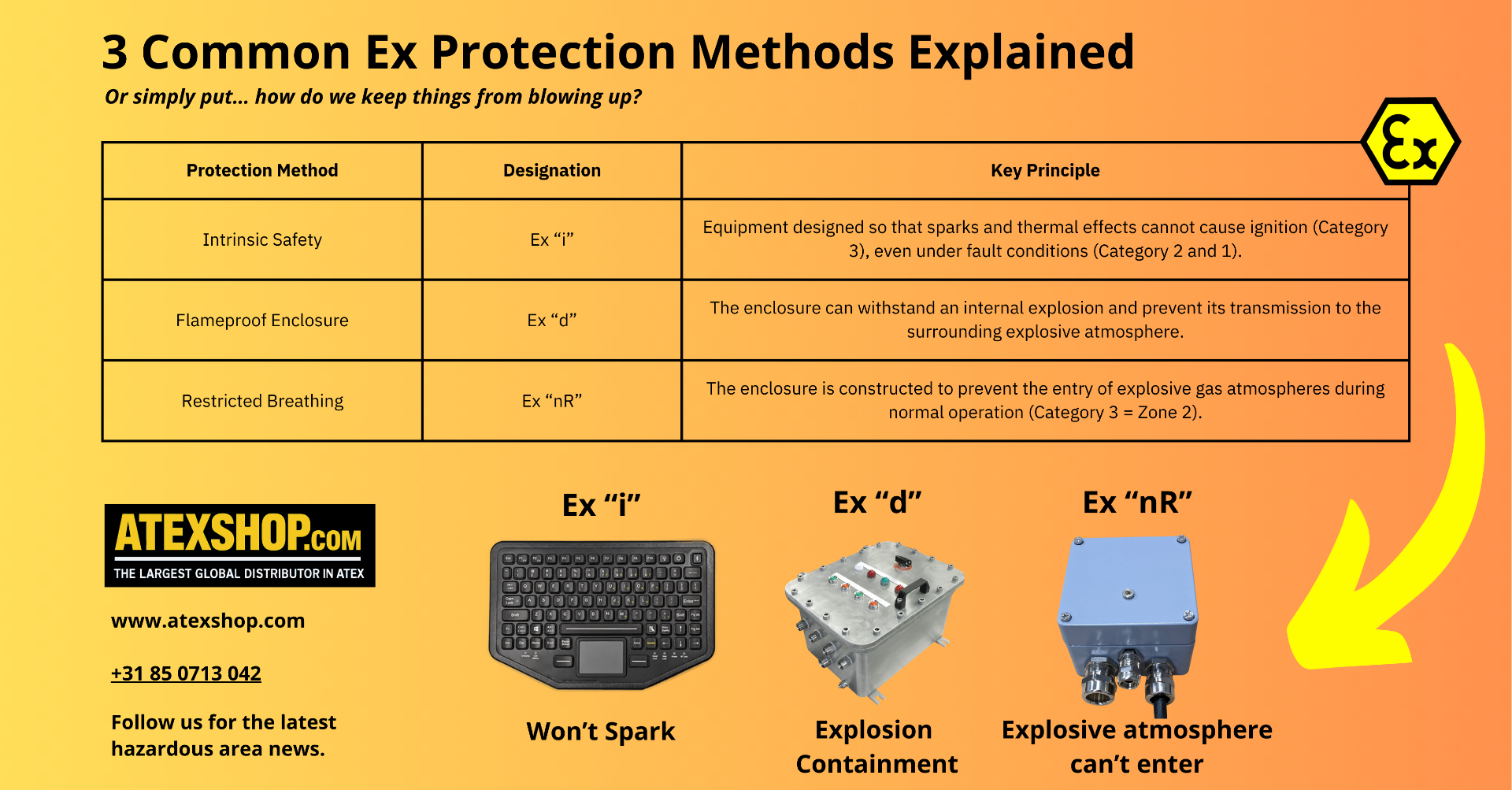

Explosion protection methods are essential to ensuring equipment can safely operate in hazardous areas where flammable gases, vapours, or mists may be present. Among the most recognized methods are Ex d (flameproof), Ex e (increased safety), and Ex i (intrinsic safety). But what about Ex nR?

Defined in the standard EN IEC 60079-15, Ex nR—or the restricted-breathing enclosure—is a lesser-known explosion protection method for equipment used in Zone 2 hazardous areas. This method focuses on preventing the ingress of explosive atmospheres into the enclosure, reducing the risk of ignition during normal operation.

Let’s dive into what makes Ex nR unique, what types of devices typically use it, and how the relevant standard (60079-15) outlines its implementation.

Overview of EN IEC 60079-15

The standard EN IEC 60079-15:2019 specifies the requirements for constructing, testing, and marking electrical equipment designed for use in potentially explosive gas atmospheres. This standard focuses on type of protection "n", which includes several sub-types, one of which is the restricted-breathing enclosure "nR".

The fundamental principle of type of protection "n" is applied to electrical equipment such that it is not capable of igniting a surrounding explosive gas atmosphere during normal operation and in certain specified regular expected occurrences [3.7, 85]. Furthermore, the requirements of the standard aim to ensure that a malfunction capable of causing ignition is not likely to occur.

Specifically, a "restricted-breathing enclosure 'nR'" is defined as an enclosure designed to restrict the entry of gases, vapors and mists [3.3, 85]. Equipment using "nR" protection is intended for use in explosive gas atmospheres of Group II.

General Requirements and Restricted-Breathing

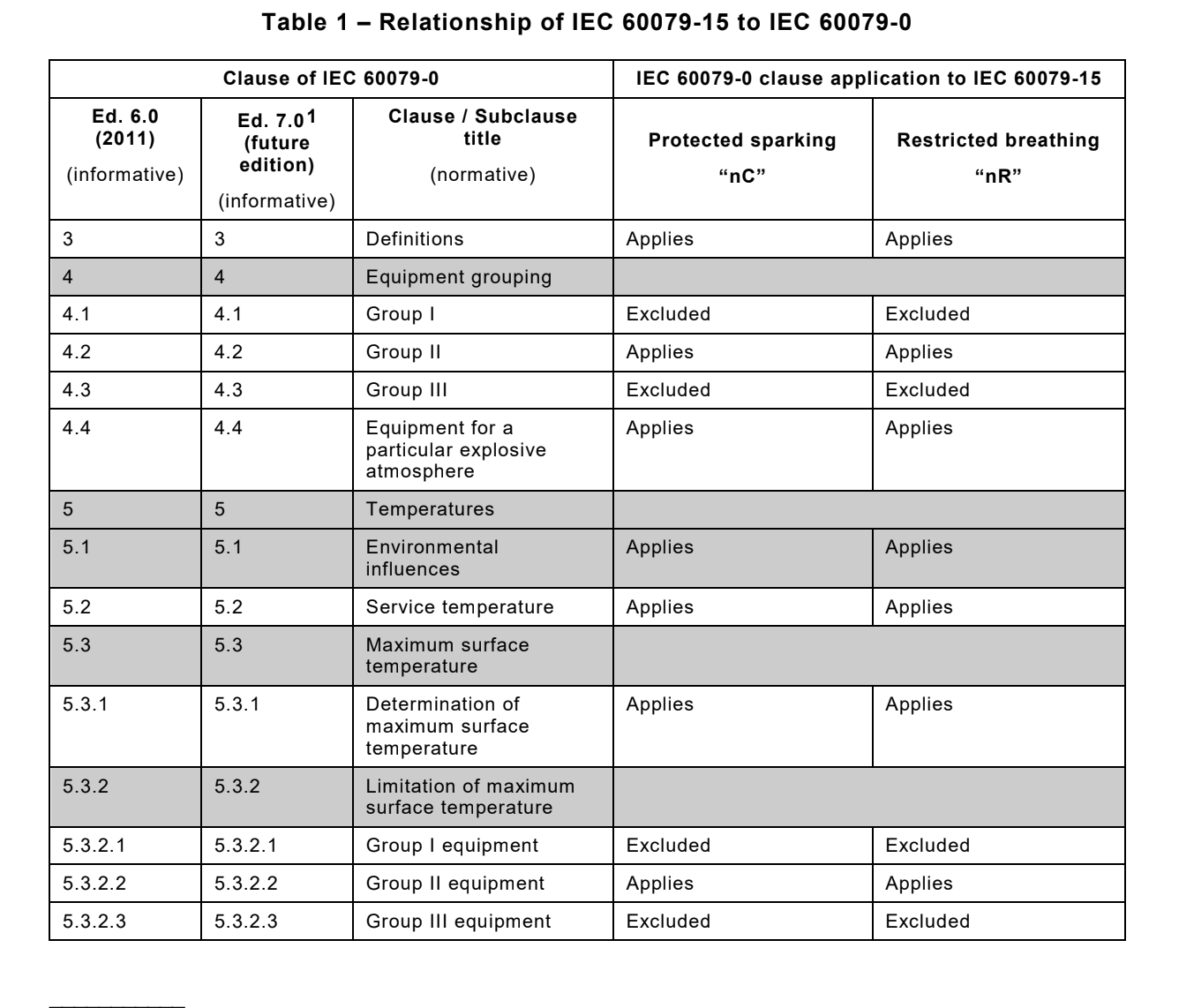

The EN IEC 60079-15:2019 standard builds on and adapts the general requirements of IEC 60079-0. When there’s a conflict between the two, the requirements in EN IEC 60079-15 take priority. Table 1 in the standard shows in detail how the clauses from IEC 60079-0 apply to the type of protection "nR". See the short snippet below, not the full table.

Core Principles and Construction Requirements for "nR"

The effectiveness of "nR" relies on limiting the ingress of the explosive atmosphere into the enclosure. Equipment employing this protection method must not produce arcs, sparks, or hot surfaces capable of ignition during normal operation and specified regular expected occurrences, unless these potential ignition sources are safely controlled or otherwise demonstrated to be safe.

The maximum surface temperature must also comply with the limits for the equipment's temperature class as defined in IEC 60079-0.

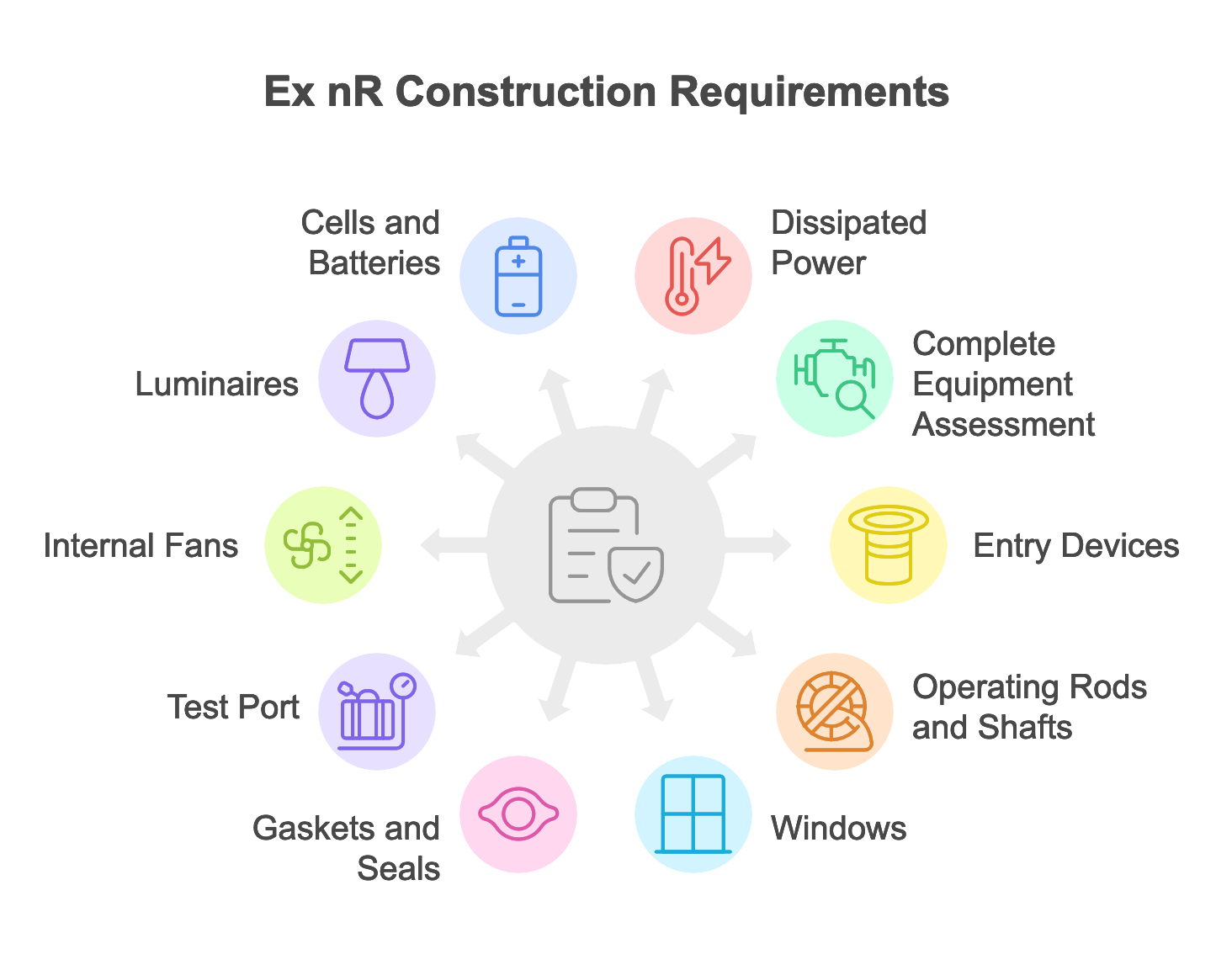

Key construction requirements for "restricted-breathing enclosures" outlined in the standard include:

-

Limitation of Dissipated Power

The power dissipated inside the enclosure must be limited so the external surface temperature stays within the maximum allowed by IEC 60079-0. If the equipment includes sparking devices or surfaces with frequent temperature cycles, the temperature must not exceed the ambient temperature by more than 20 K during normal operation. -

Assessment as Complete Equipment

Restricted breathing equipment must be assessed as a complete unit, including all options and accessories. -

Entries

Equipment must either come with entry devices already installed or include clear instructions for selecting and installing cable glands and conduit sealing devices. All glands must comply with IEC 60079-0. Integral glands are tested as part of the enclosure. -

Operating Rods, Spindles, and Shafts

Openings for these parts must preserve the “nR” protection and cannot rely solely on grease or compound for sealing, whether in motion or at rest. -

Windows

Cemented windows can be fixed directly into the enclosure wall or a frame. Gasketed windows can be installed in the wall or in a separate gasketed frame attached to the cover. -

Gaskets and Seals

These must be protected from mechanical damage in normal use. The manufacturer must specify replacement intervals in the instructions. Documentation must include proof of thermal stability across the service temperature range. Materials must have a Continuous Operating Temperature (COT) range that includes the minimum service temperature and exceeds the maximum service temperature by at least 10 K. Non-resilient seals must meet the same requirements. -

Test Port

Equipment with sparking devices or pressure-changing internal volumes during testing must have a test port. This allows testing after installation, during inspections, and for maintenance. Exceptions apply for luminaires and sealed equipment. If no test port is provided, the marking must include the symbol “X” and the instructions must state that gaskets or seals must be replaced after opening the enclosure. -

Internal Fans

Fan suction must not create a pressure drop at possible leakage points. Testing must be performed with the fan running and stopped. -

Luminaires

Mounting and reflectors must not compromise “nR” protection. Only the external surface temperature is used for classification. Instructions must address gasket replacement during re-lamping. Luminaires may be exempt from test ports if they meet certain criteria, including no sparking devices and easily replaceable gaskets. -

Cells and Batteries

Must be sealed types and comply with the “ec” protection requirements in IEC 60079-7.

Testing Requirements

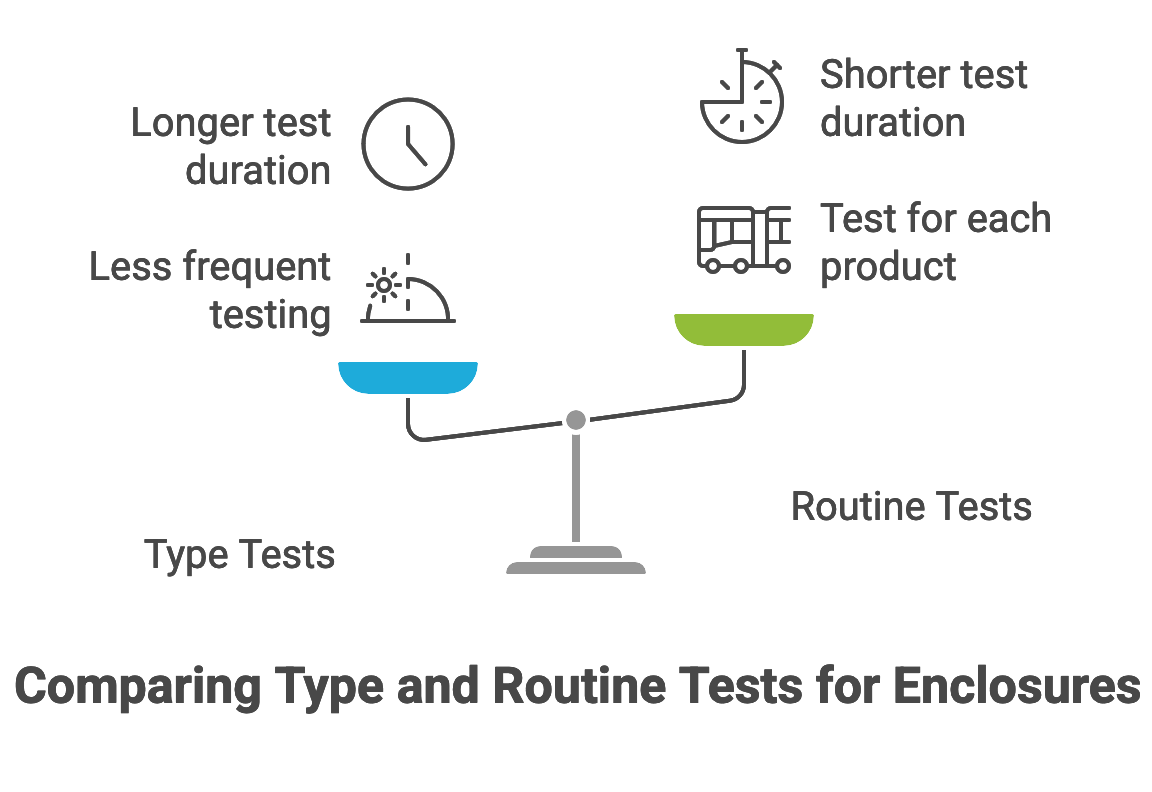

The standard specifies both type tests and routine tests for "nR" equipment.

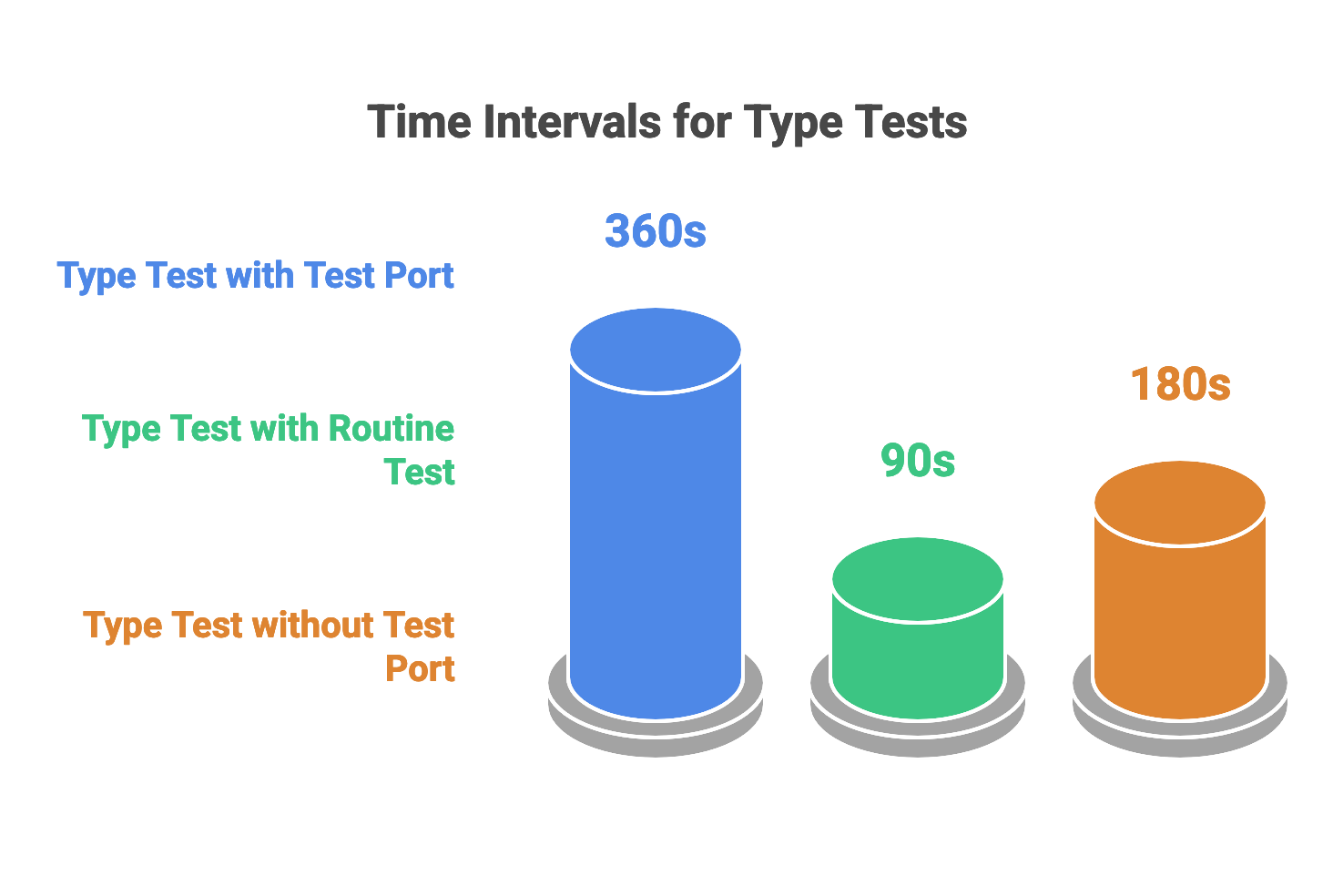

Type Tests: Clause 11.3 details the type test requirements for restricted-breathing enclosures. This involves measuring the time taken for an internal pressure difference (typically 0.3 kPa below atmospheric pressure) to halve.

The required time interval depends on whether a test port is present and if additional routine testing is performed (e.g., 360 s for type test only with test port, 90 s for type test with additional routine test with test port, 180 s for type test without test port).

Routine Tests: Clause 12.2 covers routine tests for "nR" enclosures. Equipment with normally sparking devices must always be routine tested.

Equipment without normally sparking devices but with a test port may be designed to omit the routine test if type tested at a higher level (e.g., the 360 s requirement).

The routine test procedure for equipment with a test port involves measuring the time for a pressure drop (0.3 kPa or 3.0 kPa below atmospheric) to change to a specified value within a certain time (e.g., 90 s for 0.3 kPa to half value).

Marking and Documentation

Marking on "nR" equipment must include the required elements from IEC 60079-0, plus any specific markings required by IEC 60079-15.

Examples include "Ex nR IIC Gc". If the equipment does not have a test port, the certificate number must include the symbol "X".

Warning markings may be necessary. An example is "WARNING – DO NOT OPEN, MAINTAIN OR SERVICE IN AN AREA WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT".

Documentation following IEC 60079-0 must include additional information relevant to "nR" equipment, such as:

- Information on the recommended replacement frequency for gaskets.

- Information on replacing gaskets in luminaires during re-lamping.

- Information on routine leakage testing for "nR" enclosures.

Instructions must also comply with IEC 60079-0 and include specifics like the specification for cable glands/conduit sealing devices, gasket replacement frequency (including if opening occurs without a test port), and the post-installation testing procedure.

Summary

In summary, the "nR" protection method is a key part of the "n" type of protection for electrical equipment in explosive gas atmospheres, particularly Group II, Category 3, Zone 2.

It relies on restricting gas entry into the enclosure through specific construction requirements for seals, gaskets, entries, and other potential leakage paths. All Ex nR equipment must be tested, either via type or routine testing procedures involving pressure or air flow measurements to verify this restricted breathing capability.